Plastic Injection Moulding

Modern Manufacturing in Sydney, NSW

In the realm of modern manufacturing, precision, efficiency, and versatility are paramount. Among the various techniques available, plastic injection moulding stands out as a cornerstone method for creating intricate parts and products with unparalleled accuracy and consistency.

Within this landscape, Wasson's Plastic Injection Moulding has established itself as a leader, blending innovation with reliability to meet the diverse needs of industries worldwide.

The Essence of Plastic Injection Moulding

At its core, plastic injection moulding is a process wherein molten plastic is injected into a mould cavity under high pressure. Once cooled and solidified, the mould opens to reveal a precisely formed plastic component. This method is favored for its ability to produce complex shapes, intricate details, and high volumes of parts with minimal waste.

Wasson's Plastic Injection Moulding has mastered the art of precision engineering.

Our commitment to excellence is evident in every facet of our operation, from design to delivery. Leveraging state-of-the-art machinery and advanced moulding techniques, we ensure that each product meets the most stringent quality standards.

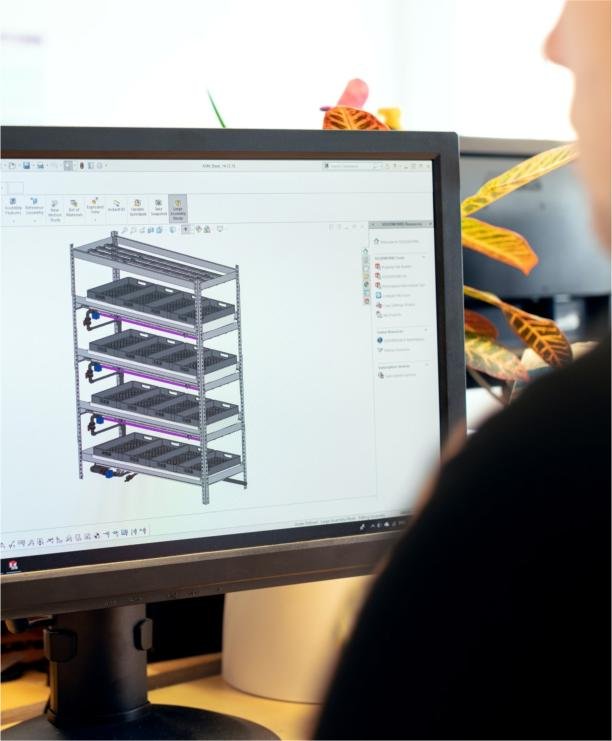

One of the key elements contributing to the precision in every product, is our meticulous attention to detail during the design phase. Utilising cutting-edge software and CAD/CAM technologies, our team of engineers transforms concepts into tangible moulds with remarkable accuracy.

This precision extends to the selection of materials, where our team ensures optimal performance and durability for every application.

Versatility Redefined

In today's fast-paced market, versatility is non-negotiable. Wasson's Plastic Injection Moulding rises to the challenge, catering to a diverse array of industries and applications. Whether it's automotive components, medical devices, consumer goods, or electronics, Wasson's adapts its processes to suit the unique requirements of each sector.

The versatility of Wasson's extends beyond the breadth of industries served—it encompasses the flexibility to accommodate various production volumes. Whether it's prototyping, low-volume production runs, or high-volume manufacturing, Wasson's scalable solutions empower businesses of all sizes to bring their visions to life efficiently and cost-effectively.

Commitment to Sustainability

In an era increasingly defined by environmental consciousness, sustainability has become a pivotal consideration for manufacturers. Recognising this imperative, Wasson's Plastic Injection Moulding is dedicated to minimising its ecological footprint throughout the production cycle.

Through strategic material sourcing, energy-efficient manufacturing processes, and waste reduction initiatives, we endeavour to mitigate environmental impact without compromising quality or performance. Additionally, our commitment to recyclable and eco-friendly materials underscores our dedication to sustainable practices.

Looking Ahead

As technology evolves and market dynamics shift, the landscape of plastic injection moulding continues to evolve. In this ever-changing environment, Wasson's Plastic Injection Moulding remains steadfast in its commitment to innovation, quality, and customer satisfaction.

We’re always looking for new an innovative ways to create products that are longer lasting. Currently, we’re investing in Metal Replacement technology which takes recycled plastic and creates products that are just a strong as metal, but won’t rust and won’t corrode.

With a legacy built on precision, versatility, and sustainability, Wasson's is shaping the future of manufacturing, one mould at a time. As industries embrace new challenges and opportunities, they can rely on Wasson's Plastic Injection Moulding to deliver excellence, today and tomorrow.